STARCELL S.P.A. Qualità e Innovazione nella produzione di pannelli compositi alleggeriti

MADE IN ITALY Produciamo in Italia nel nostro impianto high-tech di Calitri (AV)

VASTO ASSORTIMENTO Abbiamo a catalogo un’ampia scelta di pannelli con e senza finitura estetica, specificamente studiati per l’impiego in ogni settore industriale e manifatturiero

PRINCIPALI CAMPI D’APPLICAZIONE Edilizia, Ascensoristica, Nautica e navale, Arredamento per interiors, Alleggerimento marmi e mosaici, Trasporto ferroviario e stradale

STARCELL®

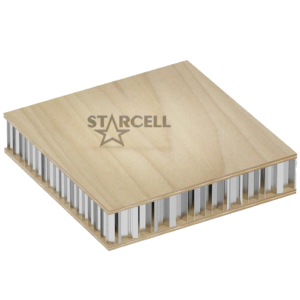

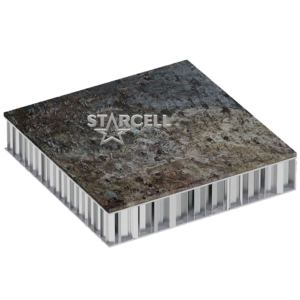

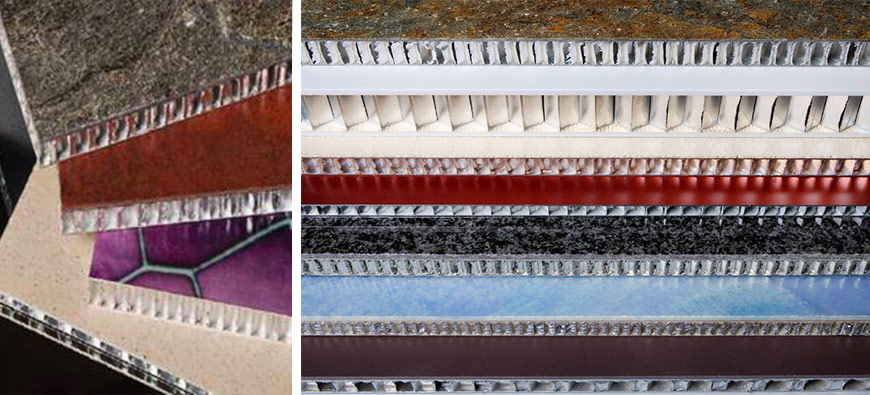

Pannelli Honeycomb a nido d’ape in alluminio, pannelli Sandwich con anima in lamiera grecata d’alluminio o in acciaio zincato e Compositi alleggeriti, in versione grezza o rivestiti con i più svariati materiali e finiture (marmi e graniti naturali, ceramica, laminati decorativi HPL e CPL, solid surfaces, legni, acciaio inox, metalli speciali).

Produzione interamente Made in Italy e distribuzione di pannelli sandwich, compositi, alleggeriti con anime sia alveolari in alluminio che in lamiera grecata d’alluminio o in acciaio zincato.

Principali campi d’applicazione: edilizia, ascensoristica, nautica e navale, arredamento per interiors, alleggerimento marmi e mosaici, trasporto ferroviario e stradale.

CAMPI D’APPLICAZIONE

I pannelli prodotti da Starcell® sono largamente utilizzati in vari settori che spaziano dall’edilizia all’arredamento, al design di ambienti e mobili per uso abitativo o industriale, ma anche per l’allestimento di treni, navi, ascensori, clean rooms e molto altro. In funzione del tipo di utilizzo, possiamo costruire pannelli speciali che rispondono pienamente a standard e normative internazionali oltre che a esigenze specifiche formulate dal cliente.

PRODOTTI

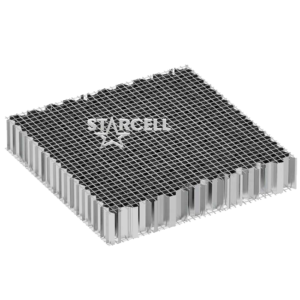

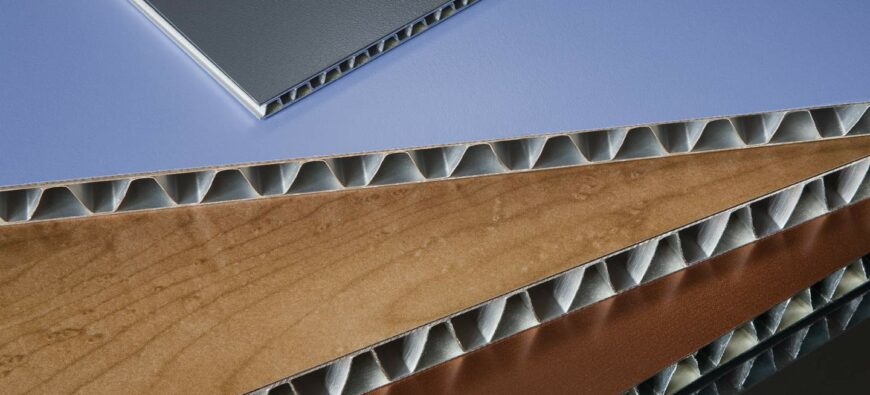

PANNELLI CON CORE GRECATO

Staluflex® è il pannello sandwich con anima in lamiera grecata d’alluminio o in acciaio zincato di produzione Starcell. Un attento controllo sulle materie prime, sul processo completamente automatizzato e soprattutto un incollaggio innovativo consentono a Starcell di offrire al mercato, a parità di caratteristiche meccaniche , un pannello con un notevole vantaggio in termini di qualità estetica, di economicità e di garanzia nel tempo. I pannelli Staluflex® sono impiegati nell’edilizia, nell’arredamento, nel navale, nel ferroviario e in tutti quei settori ove siano richieste caratteristiche meccaniche, leggerezza e resistenza al fuoco. Leggero, rigido, planare, incombustibile, 100% riciclabile, esteticamente esente da difetti superficiali, bello, italiano!

Il pannello Staluflex® può essere rivestito con i più svariati materiali e finiture (marmi e graniti naturali, ceramica, laminati decorativi HPL e CPL, solid surfaces, legni, acciaio inox, metalli speciali).

PANNELLI A NIDO D’APE SENZA FINITURA

Starcell® produce un’ampia gamma di pannelli grezzi, cioè privi di finitura estetica, che possono essere successivamente nobilitati con un assortimento illimitato di materiali. Questi pannelli sono sempre disponibili a magazzino in molte varianti dimensionali e caratteristiche tecniche (tipologia e spessore delle pelli, spessore e densità del nido d’ape, ecc.).

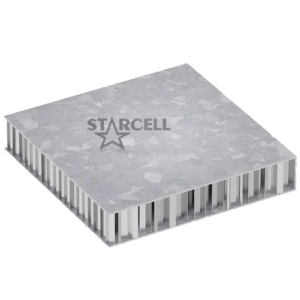

PANNELLI A NIDO D’APE CON FINITURA

Starcell® è inoltre in grado di fornire un ampio range di pannelli completi di finitura estetica ideali in tutti quei casi in cui il cliente è interessato ad ottenere un prodotto già finito e pronto all’uso. Le soluzioni proposte sono frutto di anni di esperienza nell’incollaggio e lavorazione dei materiali sui supporti grezzi anche grazie all’ausilio di aziende nostre partner, clienti nel caso di finiture di prodotti in marmo e granito. Tale ricerca è in continua evoluzione e si spinge verso materiali tecnologicamente innovativi.

SPECIALITIES

Starcell®, da sempre impegnata nella ricerca, ha sviluppato particolari soluzioni, specifiche per determinati settori merceologici e campi applicativi, con lo scopo di dare al pannello sandwich possibilità di impiego sempre nuove, integrandolo con sistemi di aggancio, bordature, lavorazioni meccaniche, inserimento di profili, rinforzi strutturali e molto altro. Il tutto al fine di creare dei veri e propri sistemi che vanno ben oltre il semplice semilavorato.

SERVIZI

Lavorazioni e personalizzazioni

Ogni pannello può essere lavorato secondo le esigenze che la particolare applicazione richiede. Starcell, in proprio oppure per mezzo di partner di fiducia altamente specializzati, è in grado di effettuare ogni genere di lavorazione su qualsiasi tipo di pannello e di materiale di finitura superficiale, secondo quanto occorre per dare un prodotto finito e completamente personalizzato.

TAGLIO A MISURA

I pannelli compositi richiedono utensili e attrezzature per il taglio di volta in volta differenti, in base al tipo di pelle utilizzata. Abbiamo una soluzione specifica per ogni esigenza di sezionamento.

NOBILITAZIONI

Abbiamo sviluppato soluzioni di incollaggio specifiche per ciascun tipo di materiale di finitura e supporto. Molti processi di nobilitazione sono automatizzati per abbattere i costi di produzione.

LAVORAZIONI CNC

Siamo organizzati con centri di lavoro CNC per eseguire ogni tipo di lavorazione sul pannello: fori passanti, asole, fresature sagomate, scontornature, predisposizioni per l’applicazione di inserti filettati e per l’innesto di profili o altri accessori.

TEST FISICO-MECCANICI

Possiamo eseguire in sede prove meccaniche di compressione, trazione, flessione e strappo e sottoporre campioni a test in camera climatica per garantire le prestazioni di un prodotto ‘custom’ nonché la sua stabilità e durevolezza nel tempo.

BORDATURE

Possiamo fornire tutti i pannelli di nostra produzione completi di bordature perimetrali, eseguite in proprio oppure da specialisti di nostra fiducia, in base al tipo di richiesta.