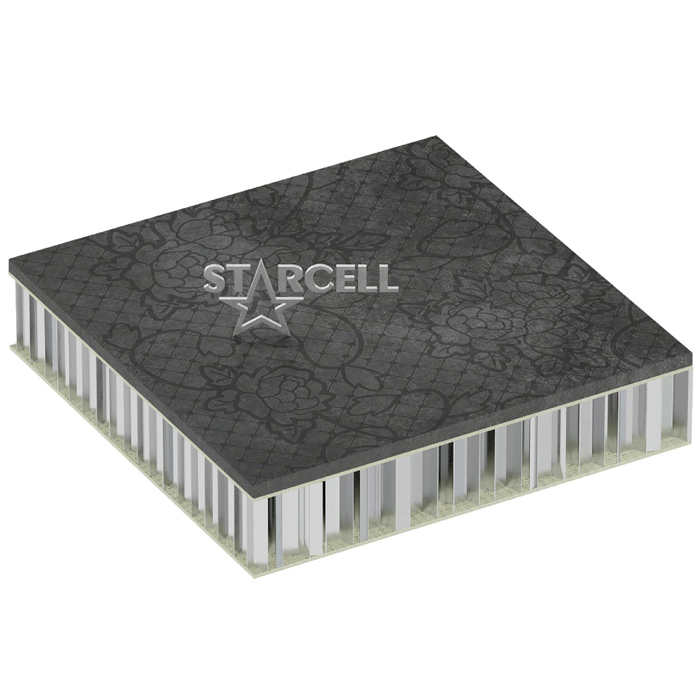

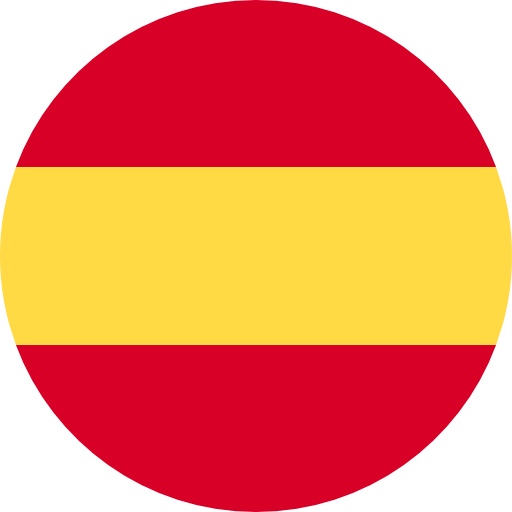

LITHOCELL®

Natural StoneMA4 honeycomb panelMA4 is a sandwich panel with a cosmetic finish consisting of a thin marble slab (4 mm). It has an aluminium honeycomb core and skins made of glass fibre fabric. It is obtained by gluing a marble finish slab to a panel without finish such as the RAWCELL® Fiber panel. Main fields of application: construction, furniture, shipbuilding, lifts.

Find out more >

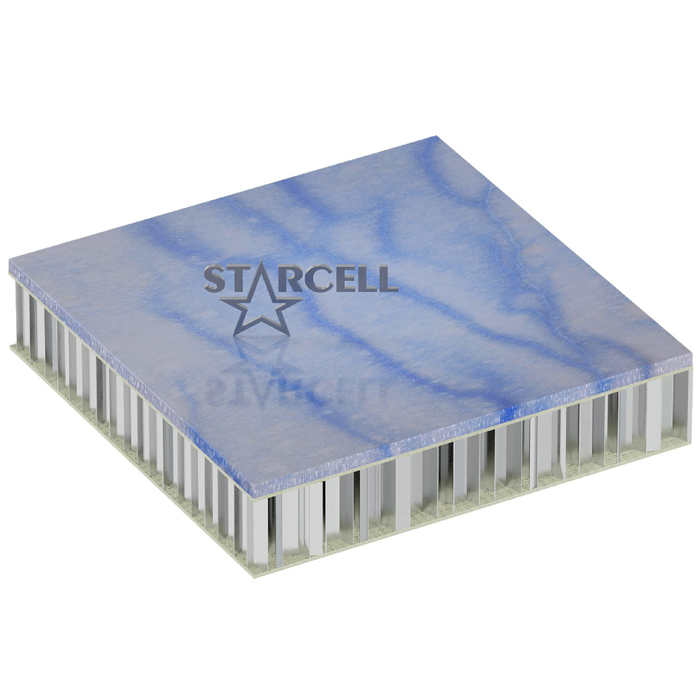

LITHOCELL®

Natural StoneGR4 honeycomb panelGR4 is a sandwich panel with a cosmetic finish consisting of a thin slab of granite (4 mm). It has an aluminium honeycomb core and skins made of glass fibre fabric. It is obtained by gluing a granite finish slab to a panel without finish such as the RAWCELL® Fiber panel. Main fields of application: construction, furniture, shipbuilding, lifts.

Find out more >

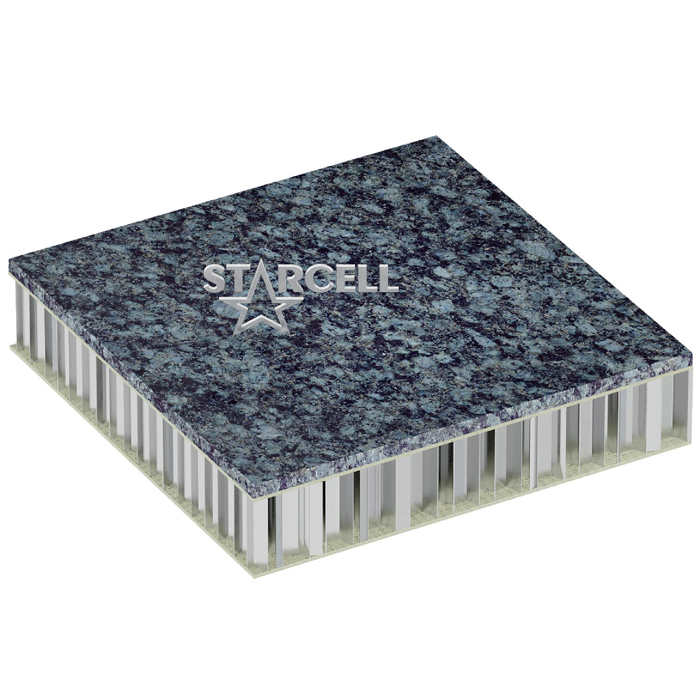

LITHOCELL®

Natural StonePS3 honeycomb panelPS3 is a sandwich panel with a cosmetic finish consisting of a split stone slab (< 3 mm). It has an aluminium honeycomb core and galvanized steel sheet skins. It is obtained by gluing a split stone finish slab to a panel without finish such as the RAWCELL® Metal panel. Main fields of application: construction, furniture, shipbuilding, lifts.

Find out more >

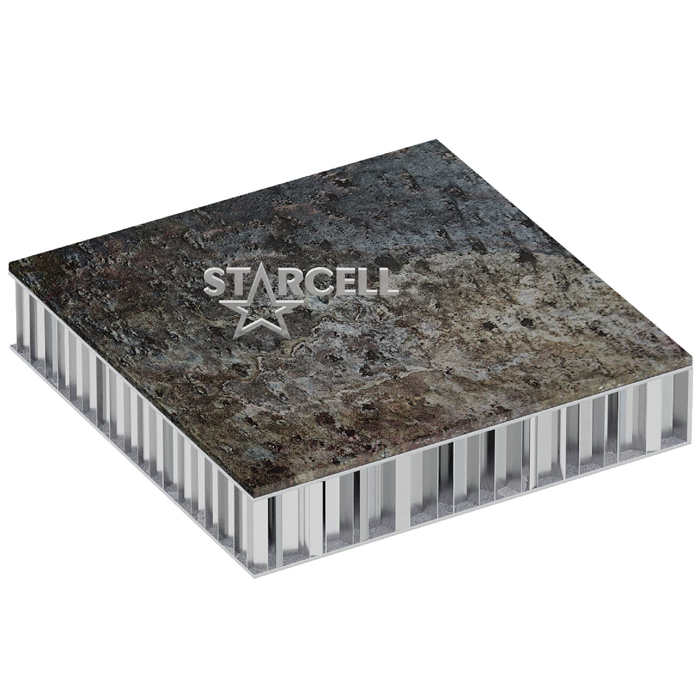

LITHOCELL®

Composite StonePR6 honeycomb panelPR6 is a sandwich panel with a cosmetic finish consisting of a reconstituted stone slab (6 mm). It has an aluminium honeycomb core and skins made of glass fibre fabric. It is obtained by gluing a reconstituted stone finish slab to a panel without finish such as the RAWCELL® Fiber panel. Main fields of application: construction, furniture, shipbuilding, lifts.

Find out more >

LITHOCELL®

CeramicCE3 honeycomb panelCE3 is a sandwich panel with a cosmetic finish consisting of a thin ceramic slab (3 mm). It has an aluminium honeycomb core and skins made of glass fibre fabric. It is obtained by gluing a ceramic finish slab to a panel without finish such as the RAWCELL® Fiber panel. Main fields of application: construction, furniture, shipbuilding, lifts.

Find out more >